Project

|

The HPRS project is a 30 month project co-funded by LIFE+ which is the European Union’s financial instrument supporting environmental and nature conservation projects. HPRS stands for HIGH PRESSURE RESINATION SYSTEM, this project aims at developing, implementing and demonstrating the innovative high pressure resination system, before moving on to the commercialisation stage. The target is to design a novel type of sustainable variable section orifice sprayer nozzles, through which resins are sprayed homogeneously at high pressure. Such a system shall be capable of improving the energy efficiency of the electric motor utilized within the blending process itself by 15%, and at the same time, of reducing resin addition by 10%, and consequently the presence of toxic substances like formaldehyde. In traditional processes the wood fibres are crushed and driven at high speed inside drums, where the resin mix is injected through nozzles at a given pressure and mixed without a careful control of the resin/wood ratio. The HPRS solution on the other hand, consists in the application of sprayer nozzles with a variable orifice diameter, where resin pressure is monitored and kept at high speed to achieve a rapid and uniform distribution of the resin over the surface of the strands or chips, hence reducing unnecessary resin consumption and achieving an overall optimization of the blending process. Whilst UF resins have desirable thixotropic properties and provide the wood panel with good structural properties, it is paramount to optimize their use in relation to the desired properties and minimize the amount of formaldehyde, known for its effects on human health.The main activities will be performed at the XILOPANTEC premises in Cigognola (Pavia, Italy) , IMAL technicians and engineers will be present during the manufacturing activities in order to assist with the fine tuning of the pilot plant. |

|

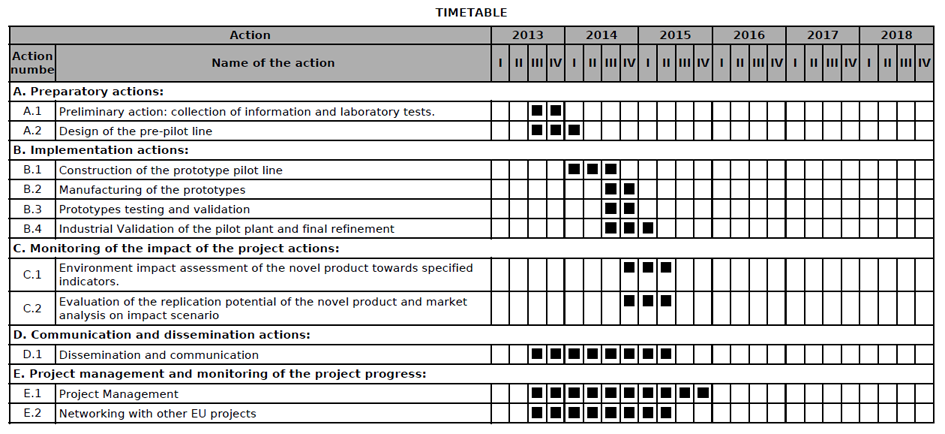

Timetable: |

|

Project Funding: HPRS stands for HIGH PRESSURE RESINATION SYSTEM, this project aims at developing, implementing and demonstrating the innovative high pressure resination system, before moving on to the commercialisation stage. The target is to design a novel type of sustainable variable section orifice sprayer nozzles, through which resins are sprayed homogeneously at high The HPRS project is co-funded by the European Commission within the ENV.E.4 LIFE Programme |